BAE Seniors Innovate to Solve Real-World Problems

The three-quarter Capstone course at UC Davis gives biological systems engineering students the skills and experiences they need to become leaders in engineering design. The teams work with industry clients and faculty advisors to develop innovative solutions to real-world problems while learning valuable skills like creative thinking, teamwork and communication as they design, build and test cutting-edge technology.

This year’s teams worked on projects ranging from remote sensing to aquaponic indoor plant growth to alginate encapsulation of caviar. Two exceptional teams are highlighted below.

Musical Enrichment for Horses

The first team—Shawn Lupo, Andrew Butler, Elijah Stockwell and Melanie Siu—developed a device that plays music for horses and lets them choose what they want to listen to. Though horses respond well to music, humans are usually the ones that choose it. The team’s client, Dr. Susan Keen in the UC Davis College of Biological Sciences, wanted to give horses more agency, as they can get bored in captivity without enrichment.

“I liked how open-ended this project was,” said Lupo. “We didn’t have anything that we were building on and we had to start from the ground up. It felt like a true engineering experience.”

After a lot of trial and error and advice from their advisor, Professor David Slaughter, the team settled on a lightweight, portable frame with three positions, bounded by PVC pipe and an ultrasonic sensor. When a horse walks into a position, it trips the sensor and starts playing one of three pieces of music—two jazz and a lullaby. Horses can then pick a favorite song or switch between them. The team also tracked how long each horse listens to each to determine which songs are most popular.

The team tested the device with five horses. Initially, some were afraid of the device or confused by it, but they got the hang of it. When the team would leave and let the horses freely use the device, the data showed that they listened on their own.

To the team’s knowledge, the device is the first of its kind and it will play a role in future research at UC Davis with the Equestrian Center’s Amy McLean. The team wants to continue developing the device to include more effective sensors, visual cues and feedbags so the horses can eat while they’re listening.

From Cheese to Plastic

Cheesemaking produces curds—the cheese itself—and whey, which can be partially processed into whey protein. What’s left over is delactosed permeate (DLP), a liquid that contains minerals and some remaining lactose. DLP is often thrown away, but in collaboration with Hilmar Cheese Company, a second team developed a continuous bioreactor that can process DLP into polyhydroxyalkanoates (PHA), a highly-degradable bioplastic.

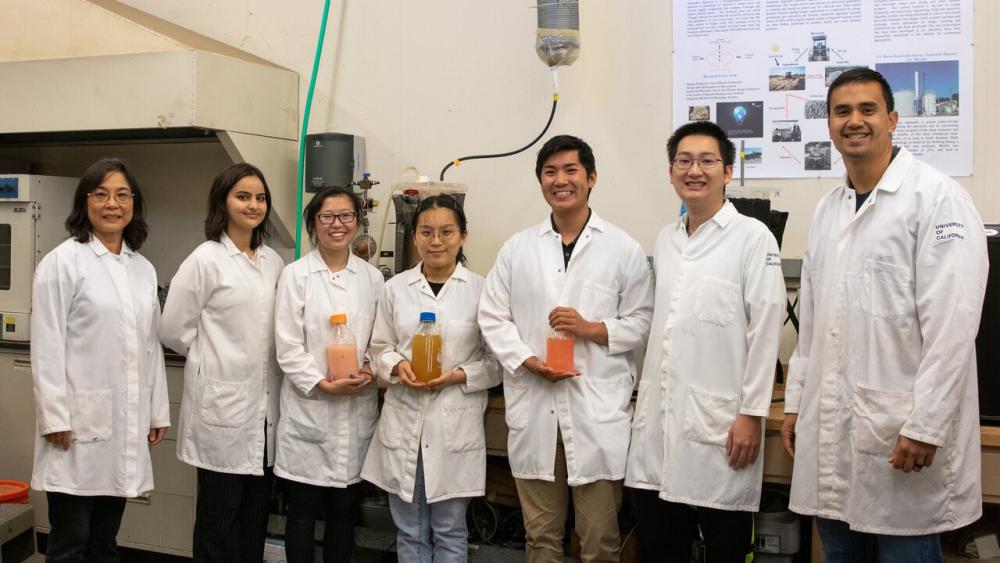

The team—Rachael Trinh, Derron Ma, Raymond Doan, Hayeon Park and Joud Alamri—was excited to design a fermentation system and build and test a bioreactor themselves for the first time.

The process starts with growing single-cell archaea in a 20% salinity sugar solution. Next, the team hydrolyzes the DLP liquid’s lactose sugars into glucose and galactose, which are easier to break down, and pours 500 mL into the bioreactor every day. As the archaea consume the liquid, they store energy in the form of PHA.

“The fact that we’re using the archaea is really interesting to me,” said Park. “I find it really cool that this little cell can produce bioplastic, and that we can grow them in our bioreactor.”

The team takes liquid samples out of the bioreactor daily and puts them in a centrifuge to separate the cell mass. The cells are treated with fresh water, which causes them to break up and release their contents. They’re then centrifuged a second time to separate the PHA that can be processed into plastic.

“We’re using a waste stream to generate this bioplastic, but it can also be recycled and disposed of in a way that’s beneficial to the environment,” explained Doan. “PHA will break down on the order of weeks and months instead of years or decades.”

In the future, the team, advised by Professor Ruihong Zhang, wants to maximize PHA yield and improve the processes for hydrolysis and processing the effluent. If successful, they hope it can be scaled up and deployed by the dairy industry. This project was supported with a grant from National Dairy Council.