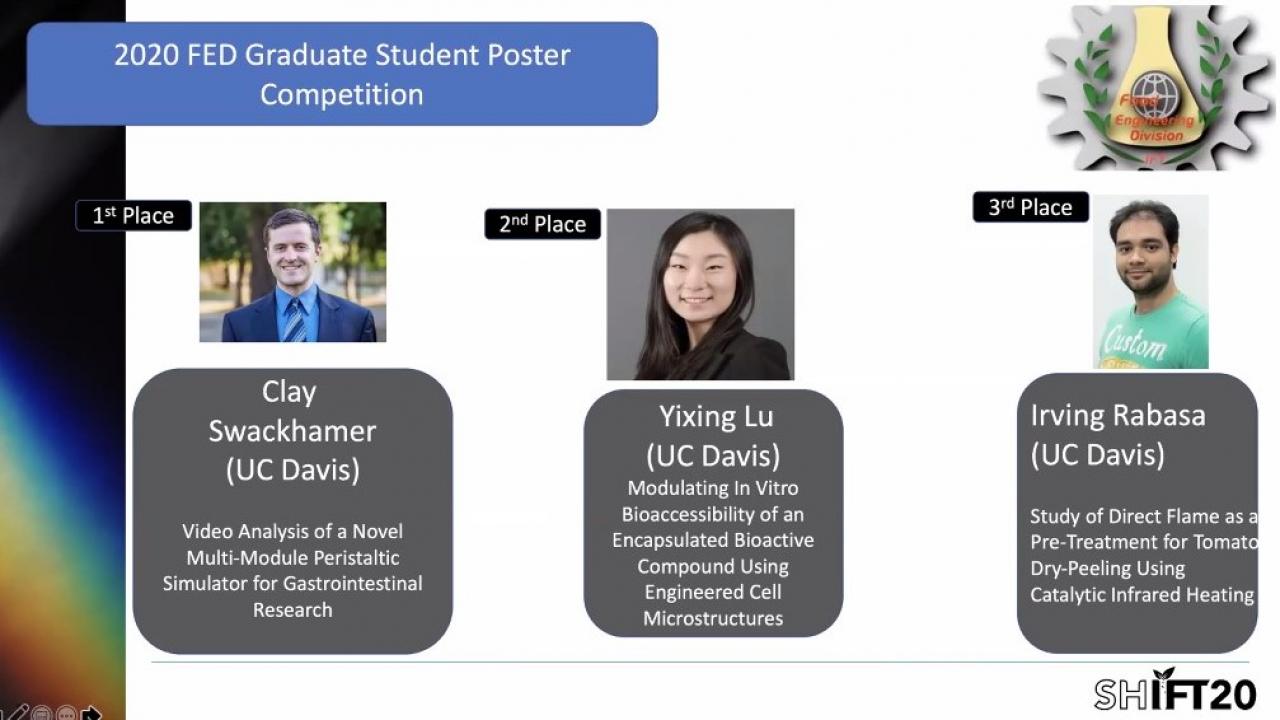

UC Davis sweeps 2020 IFT food engineering poster competition

UC Davis graduate students made their presence known at this year’s Institute of Food Technologists (IFT) Food Engineering Division graduate student poster competition, taking home all three top spots.

Biological systems engineering (BSE) Ph.D. student Clay Swackhamer, part of biological and agricultural engineering (BAE) and Food Science and Technology (FST) associate professor Gail Bornhorst’s lab, won first place. FST Ph.D. student Yixing Lu, part of BAE/FST professor Nitin Nitin’s group, finished second and BSE Ph.D. student Irving Rabasa, who works with BAE adjunct professor Zhongli Pan, finished third.

The annual competition is part of SHIFT, IFT’s annual food innovation conference that brings together food scientists and engineers from around the world to share research and ideas. As winners, Swackhamer, Lu and Rabasa presented their research at the conference social on July 14.

A short description of each of their projects is listed below:

First Place – Clay Swackhamer, Bornhorst Lab: “Video Analysis of a novel multi-module peristaltic simulator for gastrointestinal research

Swackhamer’s winning poster detailed the design, testing and motion analysis of a peristaltic simulator for gastrointestinal research. The gastrointestinal system contracts and relaxes muscles in a peristaltic motion when food is digested. Scientists have been able to simulate this in lab-based (in vitro) gastrointestinal systems, but currently can only analyze single food samples.

To help fix this, Swackhamer was part of a team that designed and built a high-throughput peristaltic simulator. He installed a high-definition camera that recorded the simulator’s motion across the 12 digestion models and used this footage to define the contraction seen in each modules. This was then used in COMSOL Multiphysics to do computational fluid dynamic modeling to understand how fluid would flow through the module.

He also compared the video to footage of a real-life gastrointestinal system, finding that the simulator was relatively accurate. Accurately simulating the peristaltic motions in the gastrointestinal tract in vitro will allow scientists to better understand how food is digested. The new system for will allow for increased screening and development of healthy food products.

Second Place – Yixing Lu, Nitin Lab: “Modulating in vitro bioaccessibility of a model bioactive compound using engineered cell microstructures”

Lu’s study examined curcumin, a model bioactive compound and the main active ingredient in turmeric, and how structural complexity at cellular and simulated tissue level influenced its release during digestion. She started by encapsulating the compounds in single yeast cells and then began clustering the cells to represent a simulated tissue. She then included an extracellular film and recorded the effect of composition and structural properties on the release during digestion.

She found that while cell clustering reduced this initial burst release from individual cells, it did not significantly inhibit the release of the encapsulated compound. In contrast, adding extracellular film significantly slowed its release throughout the digestion process. Lu’s findings are important for understanding how bioactives are released both from natural structures in plant-based foods and designed food delivery systems. They also contribute to the fundamental understanding of the role cellular structure and its assembly in a simulated tissue influences the release of bioactives, which enables scientists to engineer an bioactive release in the gastrointestinal tract for maximum bioaccesibility.

Third Place – Irving Rabasa, Pan Lab: “Study of Direct Flame as a Pre-Treatment for Tomato Dry-peeling using Catalytic Infrared Heating”

Rabasa’s study looked at pre-treating tomatoes using flame heating to make infrared dry peeling faster, more efficient. Currently, lye or steam have been used to peel tomatoes in the tomato industry, but the methods use a lot of water and chemicals. Pan’s lab has proposed an environmentally-friendly, dry peeling method using infrared heating, which has proven to be highly effective.

Rabasa’s research is further improving the technology by using direct flame heating as pre-treatment, which reduces the heating time and improves the temperature uniformity on the tomato surface, which makes the infrared peeling more effective. He hopes his work can help the technology become adopted by the tomato industry.